A slip-resistant surface is a material that does not allow a person to ‘slip’ or slide on the surface. The material must be solid, and it needs to have good glide as well as excellent resistance. It typically comes in the form of an asphalt or concrete surface but also can come in the form of flexible sheets such as those used on gym floors. A person will slip on an oil-resistant surface if there is oil, grease, or some other liquid present.

The Difference Between Slip and Oil Resistant

Oil-resistant work boots are designed to be waterproof, which means they can handle petroleum-based liquids like oil and gasoline. These types of boots are very useful for those who regularly handle these substances, as they make it possible to work without having to worry about damaging your shoes or socks. However, because of their waterproofing ability, oil-resistant work boots tend to lack the grip that slip-resistant ones have. This makes them more difficult to walk in than their slip-resistant counterparts. For example, you might notice that if you’re walking on an oily floor with an oil-resistant boot, your foot will start slipping less than if you wear a slip-resistant one. This is because oil-resistant boots are not designed to grip conventional surfaces like the ones that slip-resistant ones do. The lack of grip makes it harder to walk on oily floors with an oil-resistant boot, even if they are waterproof.

Slip-resistant composite work boots are made of materials that tend to grip surfaces more naturally than oil-resistant work boots do. For example, leather or canvas is more naturally grippy than synthetic materials like polyurethane or rubber. The more natural an item is, the better it tends to grip on certain surfaces. This makes it easy to see why slip-resistant work boots tend to outperform their oil-resistant counterparts when it comes to traction on natural surfaces like concrete or asphalt. Slip-resistant is designed to work best with your feet in many different weather conditions. If you are working around oils and chemicals, oil-resistant boots may be the better choice for your particular needs.

Definition of Oil-resistant and Slip-resistant

What is Oil Resistant?

Oil Resistant is generally a surface that resists the movement of oil-based substances. The materials seem to be easily damaged by repeated use and can be removed with solvents. This means that they cannot resist the drips and spills of liquids such as paint or ink. Solvent-based oil resistance can repel most oils, but it doesn’t last as long as solvent or air-drying. A surface that resists slipping on Solvent products is called an Aerated Concrete Surface. A slip-resistant surface intended to resist movement is called a Slip-Resistant Surface or Tacky Flooring. Air-drying oil resistance does not repel the oils at first, but after a certain amount of time, they crystalize and cannot be removed without using a solvent.

What is Slip-resistant?

Slip Resistant often uses concrete or asphalt for the base. (Aerated concrete is more popular than asphalt, though both are used). Both types of materials repel the oils. Slips on Oil Resistant surfaces are generally water-based. Water-based materials generally last longer than the petroleum petroleum-based ones. A surface that resists slipping on Petroleum products is called Aerated Concrete Surface. A slip-resistant surface intended to resist movement is called a Slip Resistant Surface. Air-drying works on all types of slip resistance, but it doesn’t get rid of the residues quickly, so they get harder to remove. The slip-resistant surfaces are applied to an area to stop movement.

Slip Resistant Surfaces are commonly used for gym floors, factories, schools, hotels, etc. Their purpose is to keep people from slipping on the ground. It can also be used for other things, such as making it easier for machines to move on the ground without slipping around. Slip-resistant shoes are also used by people who want to wear slip-resistant shoes for safety reasons.

Oil Resistant and Slip-resistant Work Boots

Oil Resistant Work Boots

Oil-resistant work boots are designed to keep your feet comfortable and dry, even in wet conditions. They are made of materials that will not absorb oil or give off any toxic vapors that can cause health problems. Oil-resistant boots can be made of all leather, treated with plastics, and soles dipped in rubber or neoprene. The outer layer may also include an impervious material such as rubber-coated nylon, polyurethane, or PVC. These types of materials repel water and oil but do not tend to be as durable as leather work boots.

Boots that are oil-resistant will not last as long. They may not have the same strength and will have a shorter useful life. As a result, they can be more expensive to purchase and maintain.

When choosing work boots, it is important to consider their oil resistance, especially if you work in an environment with oil or other slippery substances. Investing in oil-resistant work boots can reduce the risk of slips and falls in the workplace. Check out our safety footwear buying guide to find the most suitable pair for your job.

Slip-resistant Work Boots

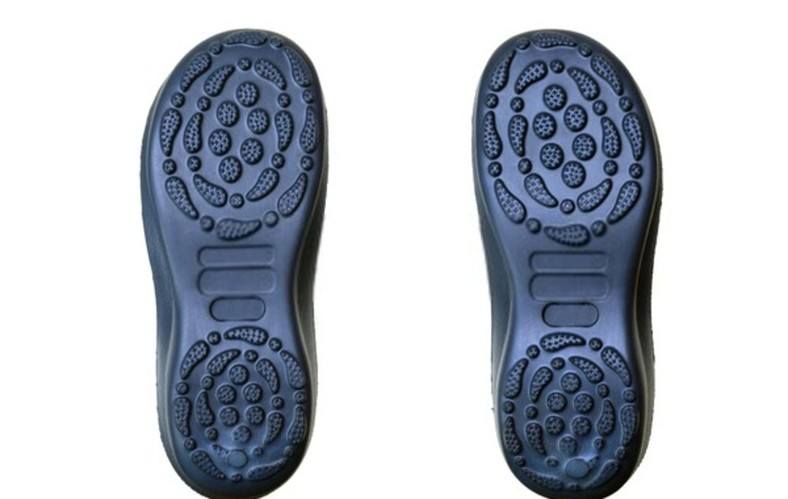

Slip-resistant work boots are designed to provide additional traction when walking on slippery surfaces like snow or ice. As a result, these walking shoes can often be identified after walking through a stretch of snow or across an icy parking lot at the end of winter. Slip-resistant work boots are commonly made with ridges around the toe, heel, and instep to provide you with added traction. The boots are also commonly black or brown leather work boots. Because they are designed to prevent slips on ice, they are worn by people who work outside, even in cold winter conditions.

Most slip-resistant boots contain hard plastic or metal studs which replace the grooves on polyurethane or neoprene styles of oil-resistant work boots. Instead of absorbing oil and other hazardous chemicals, slip-resistant designs withstand high temperatures and abrasive conditions.

Identify a Work Boot that is Oil Resistant or Slip-resistant

Oil-resistant work boots are usually black or brown leather work boots built with ridges or grooves around the toe, heel, and instep to keep the foot from slipping. The grooves may even extend around the “welt” on top of the boot for extra traction in wet conditions. Because of these features, they are easily identified as being oil resistant after walking through a processing or industrial plant with oils and lubricants used on machinery and equipment.

Slip-resistant work boots, on the other hand, are also commonly made with grooves around the toe, heel, and instep. However, they provide additional traction in conditions where there is water or ice. While slip-resistant boots may be less expensive than oil-resistant ones at first, they tend to be more durable.

Who Needs Oil-resistant Footwear?

Oil is frequently used in manufacturing, transportation, and the generation of electricity. All of these industries create a need for people with shoes that can be resistant to oil. Products like natural gas, fuel oil, and coal tar are examples of man-made petroleum-based products that could frequently come into contact with someone’s footwear.

Working in such conditions will require the wearing of specific types of footwear such as work boots or overshoes to guard against the risk. These specialized shoes should be chosen carefully depending on the activity and type of chemicals present at work.

Slipping and falling can cause serious injury and even prevent you from finishing a task. Fortunately, there are several hacks to make shoes non-slip. From using sandpaper or a nail file to create friction on the soles, to applying specialty sprays and tapes, there are various methods to increase the grip of your shoes. Additionally, look for shoes that are certified as slip-resistant for added safety.

Who Needs Slip-resistant Footwear?

Slip-resistant shoes are a must for anyone working on a floor that is wet and slippery. This includes kitchens, bathrooms, and food processing factories, all of which contain wet surfaces. For anyone working in such conditions, they will need to invest in high-quality slip-resistant shoes or boots that will protect them from falls and slips that could lead to serious accidents and injuries.

Companies such as kitchen equipment manufacturers supply people with footwear to provide slip resistance. This protects the wearer from slipping on floors wet with water, for example, when cooking or cleaning surfaces such as chopping boards or counters (Food Processing).

As well as kitchen environments, slip-resistant footwear is common in places such as aircraft hangars where personnel need protection from condensation from water vapor that occurs when planes come into contact with cold air outside (Food Processing).

What Makes a Work Boot Slip-resistant?

Slip-resistant work boots feature a special coating that allows the shoe to better shed water and other liquids. They also have wider and more padded soles that help you maintain balance and stability without having to worry about slipping on wet tiles, grass, or other slippery surfaces. These shoes also often have a rubber rand between the uppers and soles, further improving stability.

What Makes a Work Boot Oil Resistant?

Oil resistant work boots resist staining from motor oils, machine oils, hydraulic fluids, and other petroleum-based substances. The way to do this is by being manufactured from leathers that naturally repel oils. When you come home from a long day at the factory or construction site, you don’t want to have to worry about your feet being covered in motor oil. Typically these boots have a thick leather upper with rubber soles and feature a steel toe cap for extra protection from heavy objects falling on your foot.

Which Should I Buy?

You may think that this choice is just about looks or how much money you want to spend. While these criteria are important, there are two other things that will be more crucial in your decision-making process: Slip-resistant VS oil resistance.

Good quality slip-resistant shoes will offer these properties: they will allow for flexibility and comfort, they will be lightweight and durable. Different levels of resistance make shoes suitable for diverse work environments and weather conditions.

Work Boots for concrete floors are specifically designed to protect your feet from grease and solvents. These shoes must be fully waterproof, they should allow the feet to breathe, they must be nonslip, and they should conform to health and safety regulations (so look for the CE label). When choosing your new pair of oil-resistant boots, check that it has an EH rating which shows its resistance to oils/greases/organic solvents.

When purchasing safety shoes, it’s important to ensure they fit properly to maximize their effectiveness. Check out our safety shoe size charts for women and men for fitting tips and size conversions to find footwear that provides the best protection on the job.

Example of Slip-resistant Workboots

Timberland PRO Direct Attach

The Timberland PRO Direct Attach workboot has bold, black suede plies and a sleek, athletic design that the wearer will feel comfortable in. The boots are slip-resistant and can be worn with or without socks due to their slip-resistant seamless footbed. The Timberland PRO Direct Attach workboot is designed for long days of intense activity where you’ll be on your feet for hours at a time. The synthetic upper material will also allow these boots to dry quickly after washing should any dirty water remain on them.

Timberland PRO Direct Attach

If you are looking for a heavy-duty work boot, look no further than the Timberland PRO Direct Attach. These boots provide both slip-resistant and oil-resistant soles to keep you safe on the job site. They are also waterproof and have a 200g insulation to keep your feet warm and dry in any weather condition.Martens Unisex

The Dr. Martens unisex slippers are designed to give comfort and support to their wearer because it is made of quality materials that prevent any blisters or rubbing areas. The Dr. Martens unisex slippers are ideally made for people who refuse to wear any other brands of shoes because the Dr. Martens unisex slipper provides maximum comfort and long-lasting durability than other shoes, which will last for up to 500 miles.

Dunlop Protective

Dunlop Protective are slip-resistant work boots to prevent slipping and falling on worksite grounds. It’s must be safe and functional work boots for your workplace because you’ll be working in the mud or bricklayers for your job as a construction worker or any type of physical work such as landscaping, etc.

If you’re looking for top-quality work boots that are durable and lightweight, brands like Dunlop Protective Footwear have got you covered. Dunlop boots are known for their slip and oil-resistant soles and are always a popular choice for those working in construction and other heavy-duty jobs where safety matters. Learn more about work boot weight and how it impacts your workday from our comprehensive guide.

Examples of Oil-resistant Workboots

Thorogood

Thorogood has been producing American-made work boots for over a century. These boots are fully waterproof, offer tremendous traction, and are still soft enough to wear all day. The one downside is that these are not slip-resistant, but they are oil resistant.

Looking for high-quality work boots? Consider getting work boots from the most popular brands in 2023 for ultimate safety and comfort. Whether you work in construction, farming, or any other industry, investing in durable boots will help protect your feet from harm. Don’t compromise on your safety – choose from top-rated work boot brands today.

Martens

For the person who wants to impress their boss or just likes looking slick on the job, this boot is for you! This shoe offers unparalleled protection against water and oil with its revolutionary AirWair sole. The sound of the nails scratching against the floor is enough to cause anxiety in some people, so being able to hear nothing is a plus.

Danner Quarry

The Danner Quarry was released in 2005. This boot is very similar to the Icon but has better traction. It also offers some protection against water and oil, although not as much as its competitor, the Thorogood. These boots are not made in America. The Danner Quarry is better for those who are more concerned about traction than comfort. Although the boots do not slip-resistant, that function is also not very important for the person who is working on their feet all day.

Danner Quarry is a high-quality work boot brand that features slip-resistant and oil-resistant soles to keep you safe on the job site. Want to know more about where Danner Boots are made? Check out our in-depth guide to find out!

FAQs

Is slip resistant the same as oil resistant?

No, slip-resistant is not the same as oil resistant. Slip-resistant means it will have more of a grip on wet or slippery surfaces, while oil-resistant means it will have more of a grip on oily or greased surfaces.

When working with oily or greasy surfaces, it’s important to wear footwear with the proper level of slip and oil resistance. While slip-resistant shoes provide good traction on wet and soapy floors, oil-resistant shoes are designed to resist common oils and chemicals found in industrial workplaces, kitchens, and auto garages. Check out ways to make boots slip-resistant for effective methods to add slip resistance to your shoes.

What’s the difference between slip-resistant and nonslip?

There are two main differences between slip resistance and nonslip.

First, nonslip shoes have a very flat surface, while slip-resistant shoes have a large surface area with indents in them. The indents in the shoe help to grip the surfaces that you are walking on.

Secondly, nonslip shoes contain an additive that is called “sticky rubber.” This makes it, so your feet will stick to the bottom of your shoe when they are on a very slippery surface. While some slip-resistant shoes do contain “sticky rubber,” many do not have this additive, and therefore the only way for the shoe to be able to grip onto slippery surfaces is by being made with a large number of indents into the bottom of it.

What does R10 slip resistance mean?

The number in front of “R” in the shoe’s name stands for the shoe’s resistance to slip. The higher the number, the higher degree of resistance. For example, an R5 is less resistant than an R10.