Safety shoes are essential for both men and women, and wearing them can give the worker protection under standards and laws. Anyone who works with heavy machinery, dangerous items, and chemicals should wear the corresponding safety shoes to ensure that no accidents occur.

10 Types of Work Boots and Their Protective Features

There are six levels of protection provided for safety shoes: SB, S1, S1P, S2, S3, and S5. Those classified as SB have the basic safety requirements. It means:

- Tip that withstands a pressure of 200 joules;

- Sole resistant to mineral oils and hydrocarbons;

- Upholstery in synthetic material, full-grain leather or suede.

S1P protection footwear adds an antistatic sole with anti-shock and anti-slip properties. They are suitable for those who work in the industrial and manufacturing sectors, and for hotel operators and warehouse workers.

S1P shoes are more popular that have mandatory protections for many work environments. Besides the properties of the S1, they have an anti-perforation foil. Who should wear them? Anyone who carries out tasks in which they risk injuring their foot with nails or other sharp objects. They are suitable for operators in the construction and industrial sector and for those who work with wood and metal.

S2 safety shoes differ from other types. They have a water-repellent upper that makes them impermeable to liquids even in case of immersion (for 60 minutes). They have antistatic and antishock properties, a non-slip sole, and good resistance to hydrocarbons and oils.

Impact-resistant tip up to 200 joules is a must. Footwear of this type responds to the needs of various professional figures in the transport and service sectors, the pharmaceutical and food industries.

Standard S3 corresponds to work shoes with complete protection. They combine the properties of S2 with the anti-perforation midsole typical of S1 footwear. An ideal combination for many high-risk work contexts. They are indispensable on construction sites, in mechanical workshops, and the agricultural sector.

Shoes with S5 protection represent a separate category that only concerns safety boots. Also, in this case, we find the water-repellent upper, anti-perforation midsole, and toe cap with resistance to 200 joules. We also require antistatic and antishock properties, and resistance to abrasions, oils, and mineral hydrocarbons.

1. Electrical Safety

Electricians who work on a surface with contact with electricity must be cautious and attentive to the risk of electric shock. They must wear special shoes resistant to this type of risk.

Electrocution is one of the greatest dangers on construction sites. When in direct contact with high voltage electrical equipment, such as overhead power lines or transformer cabins, electrocution can cause death from cardiac arrest? Electricity flows through conductors. Conductors include metals, water, earth, but also the human body. When electrical equipment is functioning properly, they maintain the circuit between the tool, the wires, and the electrical source.

However, in the event of a machine or circuit malfunction, the operator may be part of the electrical circuit. When in direct contact with a live wire, a person may experience a tingling sensation or an intense electric shock? They can cause fatal electrocution depending on the power, frequency, and type (AC/DC) of the device. Voltages above 50V AC or 120V DC are extremely dangerous.

The ESD shoes correspond to EN ISO 61340-4-3, which borders the shoes to dissipate any static charges. They are used by professionals in the chemical industries, advanced technologies, and other environments presenting electrostatic risks.

The electrostatic loads are most uncomfortable for people who experience them, but can also create sparks. It is why they represent a significant risk of fire or even explosion. Besides, they redouble the risk of falling for people working at heights.

Although these risks are very present in certain industries, they do not correspond to those of the profession of an electrician. ESD safety shoes are only for people looking for anti-static shoes. Electricians need a shoe that offers perfect electrical insulation.

To ensure electrical safety, electricians should wear rubber boots while working. These boots offer excellent insulation and protect against electric shock. Check out this article to learn more about why electricians need to wear rubber boots while working.

2. Explosions and Flammable Material

Besides the toe and sole, a safety boot can come with metatarsal protection. It consists of having a tongue that extends from the tip of the foot to the top of the boot. This way, it protects you from sudden effects and explosions, and flammable materials that reach the top of the foot.

3. Spinning Blades

Shoes made of soft materials cannot counteract the risk of being cut by sharp objects on the road or the floor.

4. Molten Metal Protection

Burns from the fire can happen in the workplace. It can cause burns from chemicals and even common work materials like concrete. Footwear made of durable materials can prevent burns from chemical splashes, molten metal splashes, and other hazardous substances that could damage the skin of the feet. read this safety instruction.

5. Falling Objects

If you work in a place where there is a possibility of falling and throwing an object, you run the significant risk of injuring your legs in the worst way. A pair of shockproof safety boots can come to your rescue. Read this foot safety for more detail.

If you’re looking for a pair of work boots that offer reliable toe protection but aren’t sure whether to go for steel or alloy, this article will help you make an informed decision. Steel toe vs alloy toe work boots are both designed to keep your feet safe on the job, but they have some key differences. Learn more about the pros and cons of each type of toe protection.

6. Puncture Resistance

There are puncture-resistant inserts made of non-metallic materials in most boots. When the prototype version has been tested according to the relevant standard, we have confirmed the resistance to penetration.

According to EN ISO 20344, the minimum force in the test process is 1,100 N. It is equivalent to the force of a human weighing 80 to 90 kg experts on the ground when walking. The tip of a 4.5 mm thick test needle should not penetrate the specimen. We consider the test passed if the tip of the test needle does not protrude inside the specimen. Visual inspection and motion picture or electrical survey can determine it.

7. Heavy Machines and Objects

The safety boots have the precise purpose of protecting the worker such as burns, accidental falls of dangerous materials, rusty nails, or all sharp objects that can be found on a worksite. Unlike safety shoes that only and only protect the foot, safety boots also aim to protect the ankle. Therefore, they are safer for potentially more dangerous jobs. Check this article for more heavy machine and construction safety tips.

8. Cold Weather Protection

We all know that cold weather can lead to injuries like ice bite and hypothermia, and we should not overlook such dangers in the workplace. People who work outside during the winter are at risk, as are employees who work in humid or chilled environments. For more detail, please read the safety guideline for winter workers.

Not all footwear is waterproof or insulated to protect against cold, rain, and snow. So be sure to select shoes made from materials. When working in the cold, safety boots must be sufficiently insulated or lined, so that your feet stay warm? It not only increases comfort but also protects against the cold.

9. Moisture Resistance

With movement, it produces large amounts of heat and humidity. It is important to remove moisture from the body so as not to feel wet, which easily causes an unpleasant cooling of the body. The right work boots can help you maintain a pleasant feeling even during intense activity because it instantly wicks away moisture.

For those who work in wet conditions, having waterproof boots is essential. Check out this article on what materials are used for waterproof footwear to learn about the different types of waterproof materials used in work boots. Having boots that utilize high-quality waterproof materials can protect your feet from getting wet or developing blisters.

10. Slip Resistance

Some work situations require you to work on a slippery surface. When working on icy or watery surfaces, there is always a risk of falling? Choosing safety shoes with a good grip can save you from this type of risk. See the warehouse Slips Trips & Falls safety guideline.

What is a Soft Toe Boot?

The word “Soft Toe” means the non-protective toe. The upper of this boot offers no protection for your composite or fiberglass toe caps. It designates a low shoe made for walking in the countryside and intended for men.

Over time, its style has extended to ankle boots, which can be worn in any context, even formal. Nowadays, the “soft toe boot” is a model for people who want to be elegant. These comfortable working boots differ by their careful stitching on the upper.

What is a Steel Toe Cap?

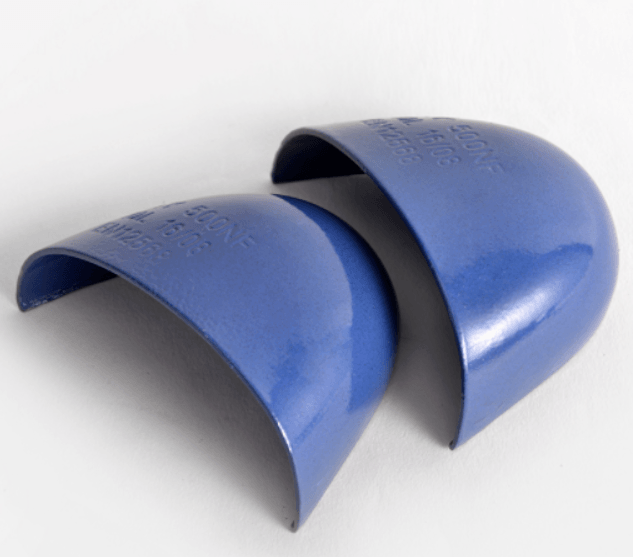

Steel Toe Cap is a division of safety shoes made of steel or composite material. It protects the wearer’s toe from falling objects and sudden compression and covers the front area where the toes are inside the shoe.

It comes with leather or other durable materials on the outside that is soft on the inside. Steel-toe safety shoes are widely used in the construction and machinery space industries. It is required by compliance with steel toe safety shoes in certain industries and work environments.

Steel toe helps protect the toes from workplace injury such as cuts, squeezes, or crushed under falling objects, sharp edges, ropes, chains, wheels, rollers or gears of machines, cameras, or grinding. In the event of accidents, the steel toe may not protect the cut or puncture the skin, muscles, ligaments, vascular nerves, or wear of the skin.

The Occupational Safety and Health Administration (OSHA) requires employers to ensure that every worker wears steel toe protective shoes when working in an area with risk of a foot injury. For example, the injuries can occur by falling objects or objects puncturing through shoes. Using steel toe shoes helps to reduce occupational injuries to the feet.

Related: Steel toe vs Composite Toe Work Boots Comparison

What is an Alloy Toe Cap?

The ferrules in aluminum alloy come with specific material and come from suitably deformed 2.5mm thick sheet metal. Therefore, they have a constant thickness. For this reason, to ensure adequate resistance to the impact and compression tests required by the EN12568S standard, they are bulkier externally. However, they allow a considerable weight reduction compared to steel toecaps.

A customized chemical and physical formulation of the alloy of aeronautical derivation gives this tip an adequate resistance to impact and crushing. People get it through the deformation molding technology that is like the corresponding steel tips.

Compared to steel, aluminum offers several advantages. It stands out most for lower weight and greater flexibility. Since aluminum is much lighter than steel, it causes less strain on the legs and feet of the wearer. As being a metal, the problem of heat and cold remains depending on the environmental temperature. Even if the heat with aluminum can dissipate more quickly than what happens with the steel.

Like steel, aluminum is also a conductor of electricity, although it is not at the same level as steel. Even with aluminum-toe boots, you may experience annoying static electricity when around machinery. However, it does not have the same effects as it would with a pair of safety boots with a steel toe.

For people who are worried about the level of resistance of aluminum, it exceeds the same safety standards as steel. So, depending on the work to be done, steel and aluminum can have the same level of protection.

Related: Steel Toe vs Alloy Toe Cap Work Boots

What is a Composite Toe Cap?

As we have seen for steel, even plastic has fibers inside it because of the injection process. And like a wooden board, it has excellent resistance if the stress we apply is along the fibers. To ensure maximum grip, people carry out all the Composite Toe Cap Shoes to have the fibers of the material arranged transversely. This toe cap offers impact force that is applied in the impact test.

The manufacturer can combine materials such as special polymers and ceramic materials to mimic the same strength of a tip protected by steel. Composite materials offer several advantages compared to steel and aluminum. For example, they do not give problems of retaining heat or cold depending on the external temperature.

They are also not excessively heavy like steel while protecting the toes from dangers. This material can meet when working in the same way as steel. The composite materials used in safety boots are also more comfortable to wear. However, as being footwear that uses relatively new technologies, they may be more difficult to find in stores.

The thickness of the composite safety toe cap is variable. On the front part, it has a considerable thickness that follows the internal shape. The external shapes are different and differ by one size.

The composite toe cap is light, non-magnetic. And a perfect electrical insulator offers exceptional thermal insulation.

Related: Steel Shanks vs Composite Toe Cap Work Boots

Proper Safety Footwear Selector & Recommended Footwear for Each Types

If you work indoors or outdoors where you are constantly in contact with water, the best solution to keep your feet dry by wearing rubber work boots. There are many options of work boots to choose the one that best suits your needs.

For example, the anti-cold boots that interior lined with suitable materials guarantee excellent insulation in case of low temperatures. Or the boots without protections for workers who are not subjected to particular risks. The white boots are ideal for the food industry and the safety boots with toe pinch and midsole are suitable for the construction industry and agriculture. You just have to choose the solution that suits you best.

For footwear alone, there are references in EN ISO standards. It has led to a very fragmented development of products and technologies for an enormous variety of models.

EN ISO 20344 regulates test methodologies and general requirements for safety footwear. Therefore, it introduces the compulsory basic type for all those jobs exposed to physical hazards daily.

Agriculture

Farmer’s work is certainly one of the toughest and needs a wide range of workwear. For the farmer, the S3 regulation is not a precise enough indicator to choose a safety shoe. The S3 standard specifies water resistance from the sole in case you walk in a puddle. Farmers who walk in the wet grass need a water-resistant upper.

For agriculture works, the best product is the GRISPORT Poseidon safety shoe. The upper is in Dakar grain leather with the original GORE-TEX Duracom MS Sportive membrane. It is a unique boot on the market.

Alternatively, we recommend a comfortable, high shoe with a grain leather upper. The BE-Rock shoe is especially suitable for winter, thanks to the innovative PrimaLoft technology known above all from jackets for mountaineers and the innovative OutDry system.

You can check out these best rubber boots for men here.

Catering

The work boots from ARTRA for kitchens, groceries (bakers, butchers, production), laboratories, and catering. They have proven themselves in recent years and are gladly reordered by many catering businesses. These boots are inexpensive, with superb quality.

The boots are also suitable for many other areas of application in craft or logistics. Most kitchen shoes for women and men are available with or without a steel toe. For practice, in hospitals, canteens, and food stalls, all working boots are also available without steel toe caps. ARTRA shoes are very comfortable because they have an excellent fit.

We’ve compiled a list of top 15 best non slip shoes for women here.

Construction

In road construction, use work shoes with rubber soles. These types of soles are HRO certified. It means they are heat resistant at high temperatures of up to 300 degrees for about 60 seconds.

The choice of construction footwear will be available because of the certifications. They meet the fundamental requirements of the EN 345 standard. It requires a steel toe cap capable of protecting the toes from effects up to an energy level of 200 Joules. The minimum certification required for the safety boots is SB (S = Safety, B = Base).

A safety shoe with S1 certification comes with a steel toe cap to protect the toes and an antistatic sole. It has an energy absorption system placed in the heel area but without an anti-puncture plate. These safety shoes are suitable for people who do not run particular risks for the sole such as warehouse workers, hotel operators, and the food industry.

Safety footwear with S2 certification is like those belonging to the S1 type, but without protection for the sole. They have an upper in leather or waterproof materials. The linings of these shoes are usually in nubuck, flower, or even suede with a water repellent treatment. It makes them equally waterproof.

They are suitable for those who work in contact with liquids of various kinds that S1 models would absorb with suede leathers.

The most common accident shoes are called S3 but also S1P and S2P and have the same characteristics as S1 and S2 shoes. They come with an anti-puncture midsole that can be in steel, fabric, or Kevlar.

Safety shoes with S4 and S5 certification are more properly boots, 100% waterproof, and used on construction sites and port areas. Boots with S4 certifications have the same characteristics as S2 shoes, while those with S5 certifications have the same characteristics as S3 footwear.

Cold Store

The UNI EN 342: 2018 standard specifies the requirements and test methods valid for clothing and safety suits for protection against the effects of environments colder than under 5 degrees.

In particular, for external temperatures ranging from 2 to -5 degrees, the temperatures from the cold store (-25 degrees) up to the temperatures from the freezer (-40 degrees). This standard tests the following values: air permeability class, thermal insulation, and breathability level. These effects include not only low air temperatures but also humidity and air velocity.

The problems resulting from not wearing cold safety shoes are many, including chilblains and cracking, not to mention worse injuries. That is why we strongly recommend that you look for a good pair of safety shoes with cold protection.

The best solutions adopted by insulated work boots to protect your feet from the cold come from the outer sole and insulating linings. In UNI EN ISO 20345 and UNI EN ISO 20347, there is a chapter dedicated to resistance to hostile environments, where a technical parameter is called “CI”. CI means cold insulation. It is the marking of the soles that have the property of insulating the feet from the cold ground.

The test is done by filling the shoe with steel balls and placing it in a cold box for 30 minutes. Then the decrease in the upper surface’s temperature of the inner sole is measured. The decrease in temperature must not exceed 10 degrees.

Foundry

A job within this foundry industry does not include a single task. Therefore, the risks are different and the foundry safety footwear you should use is different.

If you work in metal recycling, then you need to pay attention to the safety of your feet. As there are so many risky situations, such as effects, side cuts, frontal effects, and slips. Your safety footwear must have resistant materials. The best sole is the HRO nitrile rubber one, and the upper must have high-quality leather with toe cap protection (spunterbo).

For the activities with molten metals, you need specific safety shoes with EN 20349 certification against any contact with molten metals. Finally, with the lamination process, the work is normally carried out in hot, but also wet environments. It is difficult to wear an S1P safety shoe. So, you can use a shoe with water resistance that an S3 product is the most appropriate. Just check the breathability of the upper of the safety shoe for a greater feeling of comfort.

Forestry

Forestry activity takes place often outside. For this reason, we are subject to many kinds of weather (cold, heat, rain, and snow). Besides poor weather, other risks can be incurred when working in this sector.

Unlike many other occupations, the working day can be long that involves staying up for several hours. Therefore, to safeguard your well-being from injuries and posture problems, it is essential to wear extremely comfortable and ergonomic boots.

People who manage an agricultural activity also know how important it is to use excellent quality equipment. It allows the workers to get both the desired results and savings over time thanks to their long life.

New Oregon boots are an example given the characteristics of solidity, durability, and resistance. Their collections not only have a much longer duration than any other PVC or rubber boot but also greater flexibility, wearability, and considerable resistance against fungi and bacteria.

Some people may prefer the insulated hunting boots like these options in the winter time.

Healthcare

There is other footwear designed for medical and health personnel who work in hospitals. These shoes for nurses must allow you to walk with agility without slipping. They must be suitable for professionals who spend most of the day on their feet, moving from one department to another. For this reason, the boots must be comfortable and not tire the foot.

Warehouse

The warehouse is a logistic structure where human and management resources allow you to adjust the differences between the incoming flows of goods (received from suppliers or production centers) and outgoing ones (goods sent for production or sale).

The warehouse allows companies to receive, store and distribute (or sort) the references. These flows are usually coordinated, and this is one reason storage is used.

A safety shoe with S1 certification comes with a steel toe cap to protect the toes and an antistatic sole. It is characterized by an energy absorption system placed in the heel area. It does not have an anti-perforation plate. S1 type shoes are suitable for those who do not run particular risks for the sole such as warehouse workers, hotel and food industry operators. Here are some suggestions for warehouse shoes.

Farm

Working in agriculture or commercial fishing means staying in cold, wet, and dirty conditions for a long time. There is always a risk of slipping, falling, or an injury. The reliability of this footwear prevents injuries from occurring and has a tremendous impact on your well-being. It is essential to wear boots seven days a week. Carhartt offers a wide range of protective boots for agricultural work to give you the safety and comfort you deserve.

Running an agriculture, it must not only be of the best quality but also have a long life. Carhartt boots are durable and resistant to wear and tear. Carhartt boot lasts up to 3x longer than traditional PVC or rubber boots, saving you money on the total boot purchase.

Wearing pull on work boots seven days a week, all day, and in heavy conditions requires outstanding quality footwear. Your feet should not be sore after a long day of hard work. For the past 35 years, Carhartt boots have been a guarantee of comfort for farmers around the world. They are lightweight, insulate from the cold, and fit perfectly, thus preventing your feet from getting tired.

Tips for Choosing the Ideal Work Boots for Your Work Situation

Basic safety boots must always satisfy the requirements defined by the prospectus of the reference standard (UNI EN ISO 20345: 2008 for safety footwear, EN ISO 20346: 2008 for footwear protection, and EN ISO 20347: 2008 for work footwear)

1. The Right Sole and Heel

If we talk about anti-slip, ESD, resistance to high and low temperatures, we are talking about characteristics that question the choice of the sole. There are many criteria to choose from. Pay attention to the materials that polyurethane is lighter, the rubber heavier and stiffer but also more resistant to heat and abrasion.

There are also differences related to the profile and thickness of the sole. They are stiffer and heavier shoes can limit in some contexts but guarantee more heel protection and greater cushioning and non-slip grip.

They are perfect for people of robust build who work on rough terrain and appreciate rigid support when going up and down ladders. The low-profile soles are lighter and more flexible. They are suitable for those who have to walk and bend a lot during a working day and for those who work on even ground.

We have calculated that a person who works on the move for 10 hours walks an average of 30 km per day. So, it is essential to wear a light and flexible shoe as it reduces the load on the back and joints.

Puncture Proof

The heel area, in the UNI EN ISO 20345 standard that we have examined for safety boots, must always be closed and below 44 mm. There must be no holes, apart from the stitching ones.

Slip Resistant

The insole, if present, cannot be removed. If not present, the insole must be permanently attached.

For detachment resistance, they describe the verification method in ISO 20344: 2011, clause 5.2 and the detachment resistance must not be less than 4.0 N/mm. In case of tearing of the sole, the resistance must not be less than 3.0 N/mm.

A good work boot should have a sturdy and slip-resistant sole to provide traction on various surfaces, and a comfortable heel that doesn’t cause discomfort or loss of balance. You can check out the anatomy of a shoe to understand the role of the sole and heel in providing support and stability to your feet.

2. Construction Boot

Cement Construction

The cement construction method is an enormous step up in quality over the glued method. Instead of glue, it involves stitching from the upper down to the sole. It is common in the Italian production of dress shoes because it allows you to create an elegant looking high-quality dress shoe.

When looking for work boots with cement construction, check out the most popular work boots brands which offer the best cement construction boots known for their durability and practicality. Cement construction work boots are perfect for those who need comfortable work boots to get them through a hard day’s work. Choose the right work boot brand for cement construction to ensure you get the job done.

Goodyear Welt Construction

Goodyear Welt sewing technique ensures that the shoes are solid and durable. The midsole of Goodyear Welt provides the optimal support for the foot. It creates a fashionable style for the shoes.

3. Boot Weight

Safety shoes are regulated by the EN 20345 safety standard that requires them to withstand a pressure of at least 200 joules. It is the equivalent of a fall from an object weighing 20 kilograms from 1 meter in height. This protection is provided by a protective shell covering the toes and the front part of the foot.

The safety standard comes up with several classifications, each suitable for a particular type of work.

When it comes to finding the perfect work boot, boot weight is an important factor to consider. Different work boots have different weights, and the weight you choose will depend on your personal preference and job requirements. Check out Hood MWR’s article to learn more about the weights of different work boots and how to choose the right one for your needs.

4. Waterproof

The chosen shoes must withstand all kinds of external influences. Do you regularly work in damp rooms or the presence of chemicals? Plastic boots are then the ideal choice of footwear. Do you work in a kitchen or a food business? We recommend you opt for waterproof shoes with non-slip soles.

Wearing work boots or safety boots (classes S4 and S5) is recommended in damp and wet work environments, these boots being completely water repellent. Unfortunately, leather models are not always suitable for working conditions. It is advisable to choose rubber boots. These boots have the added benefit of being more resistant to chemicals, which can sometimes pierce leather.

5. Insulation

Steel-toe safety boots conduct electricity. Therefore, they are less safe than normal shoes if you have to work where there is a strong electric field. Like steel, aluminum is also a conductor of electricity, although not at the same level as steel. Even with aluminum-toe boots, you may experience annoying static electricity when around certain machinery.

Shoelaces can also improve worker safety. For example, we could replace standard cotton laces with a pair of gloves made of synthetic and waterproof materials. People who work with things that could reach high temperatures.

You should prefer laces made with a kevlar base that can withstand heat and fire. Besides, workers who have to work on difficult terrain, where the laces could untie easily, should buy gloves with a rough texture. So, you can avoid that they can be undone easily.

6. Breathability

The breathable and safe work shoes are easy to put on and guarantee a pleasant feeling of well-being. The special GORE-TEX technology is ideal for working outdoors, as it is waterproof and breathable at the same time.

For employees to wear protective shoes during their work under current regulations, comfort and fit are important. Manufacturers of personal protective equipment have developed various technologies to meet this selection criterion.

For example, we can protect the back using a cushion inside the sole which serves to absorb shocks and which can be replaced according to the weight of the operator. A reduced thickness of the sole or a modified geometry of the outer sole also relieved the user’s musculoskeletal system. Most manufacturers also offer models in different widths.

To ensure your feet stay cool and dry during long work hours, opt for synthetic materials instead of leather. Synthetic materials can offer better breathability and moisture-wicking properties, making them ideal for hot and humid working conditions. Make the switch for maximum comfort and performance.

7. Electric Surge Protection

The first classification of safety shoes, the S1 standard, is intended for dry work environments with the presence of oils and/or hydrocarbons. In leather, they come with an anti-shock and anti-static sole to withstand slight electric shocks.

The S1P standard combines the same features listed above but adds a puncture-resistant sole. They are ideal for craft workers: carpenter, drywaller, electrician, for example, where sharp or piercing objects may be present.

8. Lightweight & Comfortable

As explained above, comfort is essential for safety shoes. Do you often work in a squatting or kneeling position? Choose these lightweight work shoes that offer good freedom of movement for your feet and ankles.

A low shoe model is ideal for workers who regularly have to kneel or squat. A top model offers restricted freedom of movement, but supports the foot much better and protects the Achilles tendon. It is the reason this type of footwear is recommended in the construction industry.

The tread pattern is the part of the shoe that comes in close contact with the ground. The pattern used by the tread affects the grip, stability, and comfort of the work boot. Also, in this case, they will choose the tread pattern based on the work to be done.

People who work on a construction site may need a tread that increases stability on the ground. And workers who work on wet or oily surfaces might consider purchasing a boot with a good non-slip tread.

Excessive sweating can be a major problem. Besides increasing the sensation of heat and above all cold in the feet, the permanence of the foot in a humid environment for many consecutive hours can lead over time to favor mycosis and other annoying pathologies. For people who sweat a lot, we recommend choosing shoes with a breathable inner lining, perhaps accompanied by the use of suitable technical socks.

Choosing a work boot is a personal matter. For this reason, being able to choose between many models and variants as happens on e-commerce is a considerable advantage. However, do not underestimate the returns policy.

Final Words

There are many types of safety footwear available on the market, making it easier for anyone to choose the most appropriate for their job and needs.

Wearing the perfect article of safety footwear for your type of foot and with the right protection against the typical risks of your work will prevent accidents. Nobody wants to get injured while working, or even suffer permanent damage to their health. To avoid such risks, it is important to follow the regulations and wear safety shoes whenever necessary.